The Pros and Cons of Polyurethane Impeller

Polyurethane impellers are widely used in various industries due to their unique properties and advantages. They offer several benefits over traditional impeller materials, such as metal or plastic. However, like any material, they also have their disadvantages. In this article, we will explore the advantages and disadvantages of polyurethane impellers in different applications.

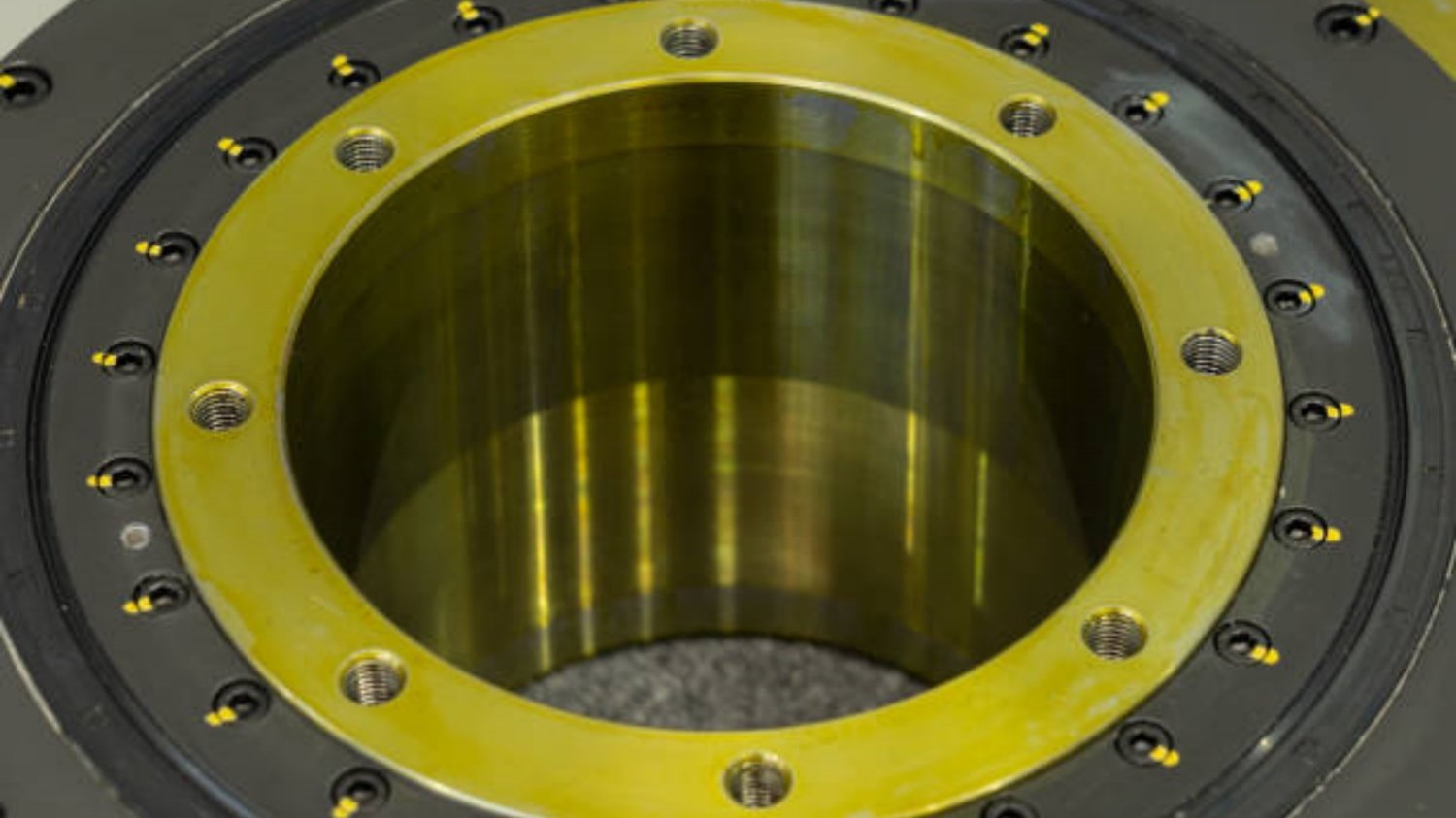

Advantage 1: Exceptional Abrasion Resistance

Polyurethane impellers excel in abrasive environments. They are highly resistant to wear caused by solid particles, making them ideal for applications involving slurries, sand, or other abrasive materials. Their superior abrasion resistance significantly extends the impeller's lifespan, reducing maintenance costs and downtime.

Advantage 2: Corrosion Resistance of Polyurethane Impeller

Polyurethane impellers are highly resistant to corrosion from chemicals, acids, and alkalis. Unlike metal impellers, which can corrode and degrade over time, polyurethane impellers remain unaffected by most corrosive substances. This makes them suitable for applications in industries such as chemical processing, wastewater treatment, and mining.

Advantage 3: Noise and Vibration Dampening

Polyurethane impellers possess excellent noise and vibration dampening properties. Their flexible nature helps absorb vibrations and reduces noise levels, making them ideal for applications that require quiet operation or where excessive vibrations can cause damage to the equipment or surrounding structures.

Advantage 4: Lightweight and Easy to Install

Compared to metal impellers, polyurethane impellers are lightweight, making them easier to handle and install. This advantage not only simplifies the installation process but also reduces the load on the equipment, minimizing wear and tear. Additionally, their lightweight nature can contribute to energy savings in certain applications.

Advantage 5: Enhanced Efficiency of Polyurethane Impeller

Polyurethane impellers are designed to optimize fluid flow and minimize turbulence, resulting in enhanced efficiency. Their smooth surfaces and precise geometries reduce energy losses and improve pumping performance, helping achieve higher flow rates and lower power consumption.

Disadvantage 1: Limited Temperature Range

One of the main drawbacks of polyurethane impellers is their limited temperature range. They are not suitable for applications that involve extreme temperatures, as polyurethane has a relatively low melting point compared to metals. High temperatures can cause the impeller to deform or lose its structural integrity, leading to performance issues.

Disadvantage 2: Lower Chemical Resistance

While polyurethane impellers offer excellent corrosion resistance against most chemicals, they may not be suitable for applications involving highly aggressive chemicals or solvents. Certain chemicals can cause the polyurethane material to degrade or swell, compromising the impeller's performance and lifespan.

Disadvantage 3: Cost of Polyurethane Impeller

Compared to traditional impeller materials like metal or plastic, polyurethane impellers can be more expensive. The cost of the raw materials, manufacturing process, and specialized tooling required for polyurethane impellers contribute to their higher price. However, considering their durability and performance advantages, the long-term cost benefits may outweigh the initial investment.

Disadvantage 4: Limited Size Range

Another limitation of polyurethane impellers is the limited size range available. While smaller impellers can be easily manufactured from polyurethane, larger impellers may require additional engineering considerations or alternative materials. This factor restricts the use of polyurethane impellers in certain applications that demand larger impeller sizes.

Disadvantage 5: UV Stability of Polyurethane Impeller

Polyurethane impellers may experience degradation when exposed to prolonged sunlight or ultraviolet (UV) radiation. UV stability additives can be incorporated into the polyurethane formulation to mitigate this issue. However, in applications where impellers are exposed to outdoor or UV-rich environments, alternative materials may be more suitable.

Polyurethane impeller advantages and disadvantages, polyurethane impeller, advantages, disadvantages, abrasion resistance, corrosion resistance, noise dampening, vibration dampening, lightweight, easy installation, efficiency, temperature range, chemical resistance, cost, size range, UV stability Polyurethane Impeller: Pros and Cons Explained Discover the advantages and disadvantages of using polyurethane impellers in various industries. Learn about their exceptional abrasion resistance, corrosion resistance, noise and vibration dampening properties, and more.