Introduction

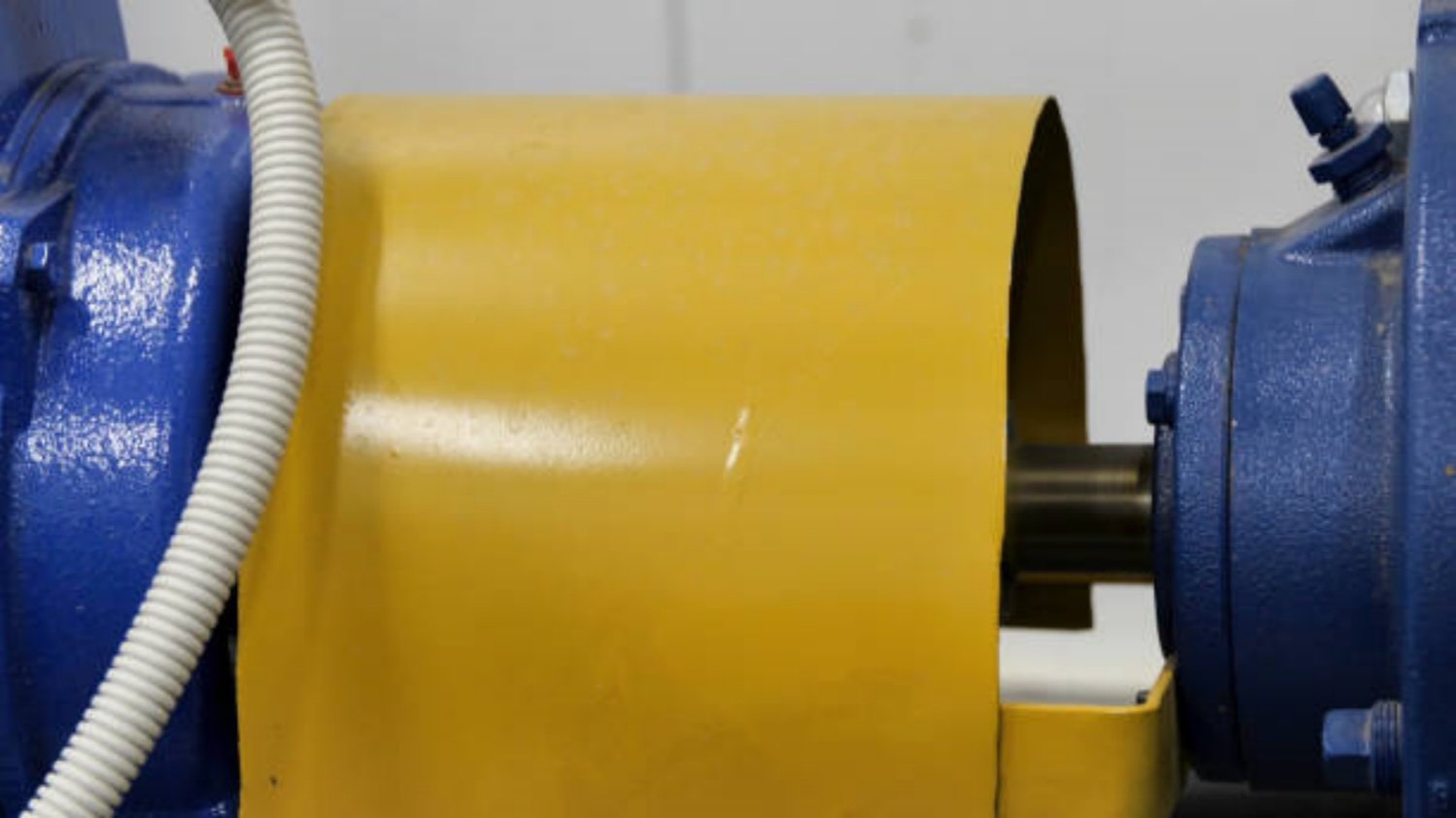

When it comes to selecting the right material for impellers, polyurethane has gained significant popularity in recent years. This article aims to provide a comprehensive guide on the material properties of polyurethane impellers, highlighting their advantages, disadvantages, and various applications.

1. Superior Durability and Wear Resistance

Polyurethane impellers are known for their exceptional durability and wear resistance. The material exhibits excellent resistance to abrasion, impact, and fatigue, making it ideal for applications involving continuous use or exposure to harsh conditions.

2. Chemical Resistance of Polyurethane Impeller Material

Polyurethane impeller material properties include high resistance to a wide range of chemicals, solvents, and oils. This makes it suitable for applications in industries such as chemical processing, wastewater treatment, and oil refining, where exposure to corrosive substances is common.

3. High Load-Bearing Capacity of Polyurethane Impeller Material

One of the key advantages of polyurethane impellers is their ability to withstand heavy loads. The material possesses excellent load-bearing capacity, allowing it to perform reliably even under extreme conditions.

4. Impact and Vibration Damping

Polyurethane impellers have inherent shock-absorbing properties, which enable them to dampen vibrations and reduce the risk of mechanical failures. This makes them particularly suitable for use in pumps, mixers, and other equipment that operate at high speeds or experience frequent shocks.

5. Noise Reduction of Polyurethane Impeller Material

Polyurethane impellers can effectively reduce noise levels in various applications. The material's ability to absorb and dampen sound vibrations makes it an excellent choice for industries that prioritize noise reduction, such as HVAC systems, automotive manufacturing, and ventilation equipment.

6. Temperature Resistance of Polyurethane Impeller Material

Polyurethane impellers exhibit good temperature resistance, allowing them to withstand both high and low temperatures without significant degradation. This property makes them suitable for applications in extreme environments, including cryogenic and high-temperature processes.

7. Dimensional Stability

Polyurethane impellers maintain their dimensional stability even under variable operating conditions. This means that they can retain their shape and structural integrity, ensuring consistent performance over time.

8. Easy Machinability of Polyurethane Impeller Material

Another advantage of polyurethane impeller material properties is their ease of machinability. The material can be easily molded, cast, or machined into intricate shapes and designs, allowing for customized impeller production.

9. Lightweight

Despite their impressive strength and durability, polyurethane impellers are relatively lightweight compared to other materials like metals. This lightweight nature makes them easier to handle, install, and transport, while also reducing the risk of excessive load on equipment.

10. Wide Range of Applications of Polyurethane Impeller Material

Polyurethane impellers find applications in various industries and sectors. Some common uses include water and wastewater treatment, chemical processing, food and beverage production, mining, and automotive manufacturing. Their versatility and excellent material properties make them a preferred choice for many demanding applications.