What are polyurethane rubber tubes?

Polyurethane rubber tubes are a type of elastomer made from polyurethane material, a synthetic polymer. These tubes are popular in various industries because of their outstanding performance attributes, including high resistance to wear and tear, abrasion, corrosion, and chemicals. Polyurethane rubber tubes have excellent mechanical properties, including flexibility, durability, and strong load-bearing capacity.

Benefits of Polyurethane Rubber Tubes

Polyurethane rubber tubes have a range of benefits that make them a popular choice in different applications. Firstly, they have a high resistance to abrasion, tearing, and puncture. They are also resistant to oils, chemicals, and UV radiation, making them a good choice for outdoor applications. Secondly, they have excellent mechanical properties, making them strong, flexible, and resistant to impact, which means they can withstand heavy loads and pressure. Lastly, they are highly durable and offer long-lasting performance, making them a more cost-effective option compared to other materials.

Applications of Polyurethane Rubber Tubes

Polyurethane rubber tubes have numerous practical applications across various industries. They are commonly used in hydraulic and pneumatic systems, primarily because of their durability and resistance to pressure and forces. Additionally, they are useful for industrial hose applications, such as oil and fuel transfer, where they can provide fluid movement under high pressure and temperature conditions. Other applications include medical equipment, automotive industries, food and beverage processing, and construction machinery.

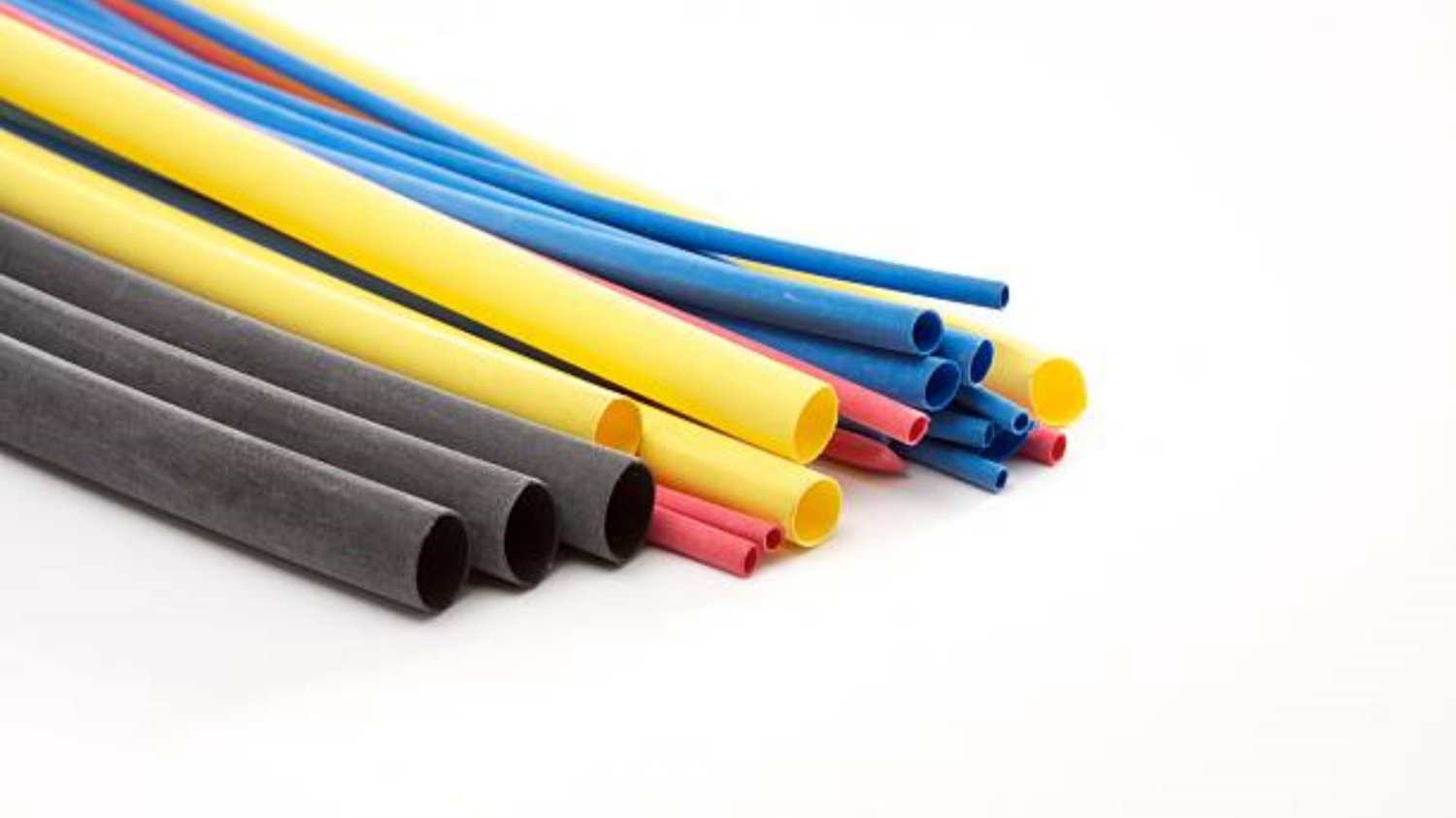

Types of Polyurethane Rubber Tubes

Polyurethane rubber tubes are available in various types, depending on the application requirements. Some of the most common types include ether-based and ester-based polyurethane tubes. Ether-based tubes have better low-temperature performance and hydrolysis resistance, while ester-based tubes are more resistant to chemicals and abrasion. Other types of polyurethane rubber tubes include clear and colored tubes, antimicrobial tubes, high-pressure tubes, and reinforced tubes.

Choosing the Right Polyurethane Rubber Tube

Choosing the right polyurethane rubber tube is crucial for ensuring optimal performance in different applications. To determine the appropriate tube type, consider factors such as temperature, pressure, chemical exposure, and environmental factors. Specific applications may require specific types of tubing, such as reinforced tubes for high-pressure applications or FDA-approved tubes for food and beverage processing. It is essential to consult with experts in the field to select the right polyurethane rubber tube for specific applications.

Maintaining Polyurethane Rubber Tubes

To maintain polyurethane rubber tubes' optimal performance and lifespan, it is necessary to take proper care and maintenance measures. Regular inspections to identify signs of wear, damage, or corrosion is essential. Additionally, maintaining appropriate pressure levels, conducting routine cleanings, and observing safety guidelines can extend the tubes' lifespan.

Replacing Polyurethane Rubber Tubes

While polyurethane rubber tubes are highly durable, they eventually wear out and require replacement. The right time to replace the tubes depends on factors such as exposure to the environment, operating at maximum pressure, and high abrasion. Regular inspections and maintenance can help detect when replacement is necessary and prevent operational downtime. Replacing polyurethane rubber tubes requires expert knowledge to avoid incorrect installation, which can result in complications and injuries.

Cost of Polyurethane Rubber Tubes

The cost of polyurethane rubber tubes varies depending on factors such as tube size, type, and the quantity required. While polyurethane rubber tubes may initially cost more than other materials, their durability and long lifespan make them a cost-effective choice in the long run. Replacing tubes frequently can result in added costs and operational downtime, making polyurethane rubber tubes a wise investment.

Advancements in Polyurethane Rubber Technology

The polyurethane rubber industry is continually evolving, and new technology advancements continue to improve the material's properties and applications. Recent advancements include improved chemical resistance, flamability resistance, and high-temperature performance. Additionally, bio-based polyurethane rubber that is renewable and sustainable is emerging as an environmentally friendly polyurethane rubber alternative.

The Future of Polyurethane Rubber Tubing

Polyurethane rubber tubing's use is projected to increase due to its high-performance attributes, durability, and versatility across various industries. Further, the expected advancements in polyurethane rubber technology will improve the material's properties and expand its applications. Polyurethane rubber's eco-friendly options will also drive market growth in the future.